Product: BOILERWATCH® MMP II-SSX

The BOILERWATCH® MMP II-

The system is completely non-

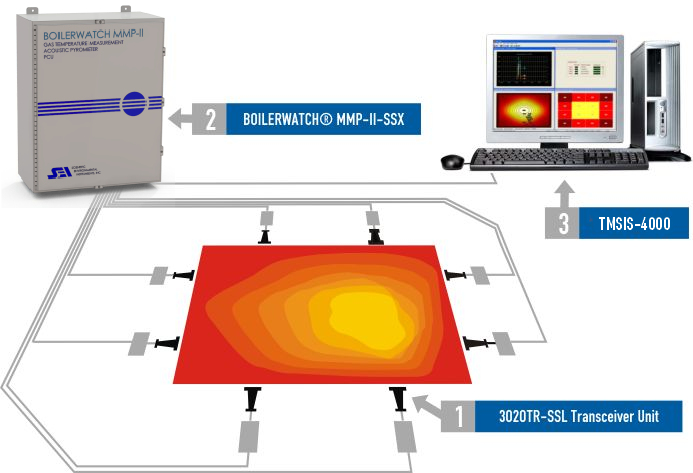

Acoustic transceivers are mounted on the outside of walls of the heater/boiler, and a high intensity acoustic signal is launched through the gas stream.

The BOILERWATCH® MMP II-

The system is completely non-

Acoustic transceivers are mounted on the outside of walls of the heater/boiler, and a high intensity acoustic signal is launched through the gas stream.

Since the distance between the sound source and receiver is known and fixed, the average temperature of the gas along the acoustic path is computed from an accurate measurement of the sound signal’s transit time.

BOILERWATCH® MMP II-

3O2OTR-

Pneumatically driven acoustic sound source and receiver.

Mounts on exterior furnace /heater wall, and provides acoustic transmitter and receiver functions for balanced-

BOILERWATCH® MMP-

Processor Control Unit (PCU)

Provides temperature measurement capacity for up to eight (8) independent paths , or up to a twenty-

TMSIS-

Features include: Industrial computer with pre-

3020TR-SSL Transceiver unit – Wave Guide and Preamplifier

Wave Guide

| Material: | Stainless Steel 316L |

| Dimensions: | 200mm flange diameter, 325mm length |

| Flange: |

In accordance with ASTM standard 3- |

| Weight: | 26 lb. (11,8 Kg.) |

|

Temperature Environment: |

Flange: +450ºF (+232ºC) max.; Ambient Air: +130ºF (+54ºC) max. |

|

Noise generated: |

Inside: 126bB. Outside: 0dB |

Preamplifier

|

Ambient Air Temperature: |

+ 140 ºF (60ºC) maximum, No solar loading on cabinet |

|

Enclosure: |

343H x 288W x 130D mm |

|

Weight: |

14 lb (6,4 Kg) |

|

Industrial Standards: |

NEMA/EEMAC Type 4,12, 13. IEC 60529, IP66 |

BOILERWATCH® MMP II-SSX

|

Ambient Air Temperature: |

+ 130 ºF (54ºC) maximum, No solar loading on cabinet |

|

Enclosure: |

762H x 610W x 356Dmm |

|

Weight: |

110 lb (50Kg) |

|

Industrial Standards: |

NEMA/EEMAC Type 4,12, 13. IEC 60529, IP66 |

TMSIS-4000

|

Number of Ports: |

Two minimum and up to sixteen maximum |

|

Number of Paths: |

Up to twenty- |

|

Measurement Range: |

32ºF to 3500 ºF (0ºC to 1927 ºC) |

|

Temperature Units: |

English or Metric (ºF or ºC) |

|

Resolution: |

12 ºF (6.7 ºC) for 20 meter path length @ 2000 ºF (1093ºC) |

|

Accuracy: |

Better than 0.5% |

|

Measurement Acquisition Time: |

5 seconds per path typical |

|

Data Output: |

Analog Output 4- |

|

AC Power Input: |

120 to 240 VAC, 50/60 Hz. |

|

Air Pressure to Sound Source: |

Air Service. 60 – |

|

Air consumption: |

5 bar = 2.26 m3/min (No Constant) |