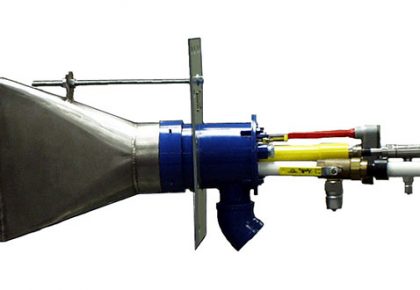

Product: Horn Igniter

The Forney horn igniter is designed to be a direct replacement for the OEM igniter on tangentially fired boilers. This igniter features improvements such as the high energy spark igniter (HESI), optical flame detector and the ignition air distribution ring. These three features combine to produce a highly reliable igniter. The HESI produces a consistent spark due to its foul resistant design, while the optical detector proves flame without physical contact.

Forney’s horn igniter offers reliable single or dual fuel ignition and warm-up for tangentially fired burners and is designed for maximum flame stability and detection.

Designed for maximum flame stability on tangentially fired burners, Forney’s horn igniter offers reliable

single or dual fuel ignition and warm-up.

The Forney horn igniter is used on tangentially fired boilers for burner ignition and warm up, typically as a Class 2 igniter. Depending on customer needs, Forney offers either a single or dual fuel horn igniter. The single fuel horn igniter fires either oil or gas. The dual fuel horn igniter fires either oil or gas without a change of equipment, allowing for a quick and effortless change over of fuel.

Both horn igniter assemblies consist of a mounting plate, an oil or gas gun for the single fuel horn igniter or a combination oil and gas gun for the dual fuel horn igniter, a High Energy Spark Igniter (HESI), a combustion air tube, an optional flame detector, and a horn. The major components are fastened to the igniter front plate with easily removable connections to simplify maintenance. The oil and gas connections utilize stainless steel braided hoses and optional quick disconnect couplings.

The optional flame detector is mounted on a 1” NPT sight tube, which provides an unobstructed view of the flame inside the horn. Since the etector is mounted to the igniter windbox, it does not require cooling air. On retrofit applications, the existing horn (diffuser) may be reused, if it is not damaged or deteriorated. As a result, the installation requires only replacing the front plate and internal hardware, minimizing costs.

Specifications

Fuel: No. 2 Oil, Propane or Natural Gas

Oil

-

- Capacity Rating: 2 – 4 MBtu (consult factory for higher output, available up to 15 MBtu)

-

- Fuel Pressure: 60 – 125 psig

- Atomizing Media Pressure: 25 psig differential over oil pressure

Gas

-

- Capacity Rating: 2 – 4 MBtu (consult factory for higher output, available up to 15 MBtu)

- Fuel Pressure: 12 – 25 psig

Cooling/Combustion Air

-

- Flow: 120 SCFM

- Pressure: 4 – 6 inches w.c. above furnace pressure

HESI Specifications:

Input Voltage: 120 to 240 VAC, 50/60 Hz

Input Power: 120 VAC @ 1.5 A (2-A fuse); 240 VAC @ 0.75A (1-A fuse)

Output Voltage: 2000 VDC

Output Energy: 12 joules per spark

Spark Rate: 3 per second (approximately)

Duty Cycle: 50% at temp 0°F to 135°F ( -18°C to 57°C ) Ambient

- Igniter Capacity

Up to 4 MBtu/hr for ignition and/or support of main gas, oil or coal burners and up to 15 MBtu/hr with an auxiliary gun. Depending on burner capacity, the horn igniter is capable of supporting Class 1 or 2 operations. - Dual Fuel Capability

The single fuel horn igniter fires either oil or gas; the dual fuel horn igniter fires either oil or gas without any change of equipment. - Stable Flame

Combustion air is evenly distributed throughout the horn for reliable operation; Forney’s design does not include an eddy plate, thus reducing coke buildup and overheating. - Optional Flame DetectiOn

The flame detector senses flame inside the horn and discriminates from flames outside the horn. - Reliable IgnitiOn

The High Energy Spark Igniter (HESI) is fixed at the most efficient light-off position for repeatable ignition.

Horn Igniter Technical Bulletin

Publication Number 404006-07