Product: adVantage® Duct Burner

adVantage® duct burners perform in the most challenging conditions.

Premium components and patented technology join to perform like no other duct burner.

This design works best in advanced gas turbine applications, especially those with water or steam injection, where low emissions are critical.

Forney’s adVantage® duct burners are optimized for advanced gas turbines that support the critical low emission requirements for water or steam injection applications.

Duct Burners from Forney Corporation meet the complex needs of the combined cycle and cogeneration industry. Forney’s adVantage® duct burner is the choice for the most demanding conditions of advanced gas turbine applications, where inlet oxygen of the Turbine Exhaust Gas (TEG) is low or the water vapor is high.

Low inlet oxygen and high water vapor levels have typically required duct burners to be provided with augmenting air. Forney’s adVantage® design reduces or even removes the need for augmenting air by using an exclusive mixing process, that optimizes the existing oxygen in the turbine exhaust.

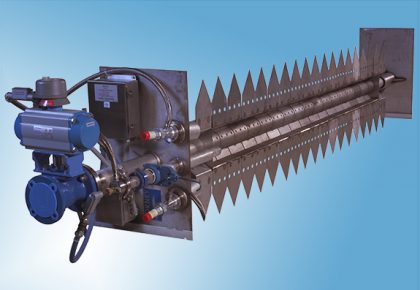

The outstanding CO and VOC emissions performance is a product of turbulent mixing from the adVantage® duct burner design. The lower emissions available from the Forney adVantage® duct burner can help to offset other plant costs such as downstream emission reduction equipment.

Less sensitivity to inlet flow distribution is another benefit to the Forney adVantage® duct burner. This means the same low emission performance even with wide TEG flow profiles. Through the exclusive mixing process, Forney adVantage® duct burner produces a shorter flame length for the same pressure drop as recirculation type burners. Shorter flame lengths require less downstream duct distance and allow a greater residence time to mix with the bulk TEG and improve temperature distribution from the burner.

Scope of Supply

Forney supplies a complete scope of equipment with each duct burner system.

Typical Scope:

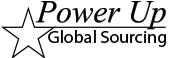

Horizontal (or vertical) Burner Elements

Integral Flow Baffles

ANSI B31.1 Fuel Skid

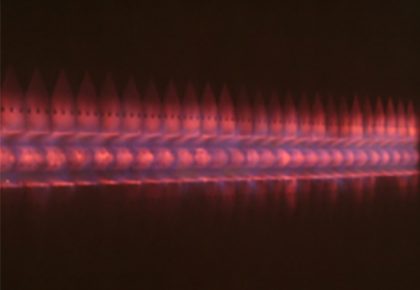

Burner Management System

Redundant Scanner Cooling Air Blowers

MAXFire® Igniter with HESI

Flame Scanner

Optional Scope:

Pressure Reducing Station

Fuel Flow Measurement

CFD

Individual Element Isolation

Interconnecting Piping

ANSI B31.3 Fuel Skid

Application Specifications

Duct cross sections: 3 to 50 feet (0.91 to 15.25 meter)

Heat inputs: 10 to 1100 MMBtu/hr (2.93 to 322 MW)

Inlet oxygen levels: ≥ 10.5% wet without augmenting air

Inlet H2O: ≤ 20% without augmenting air

TEG distribution to the burner: ± 20% of the average velocity over 90% of the cross section

Typical Emissions

For most advanced gas turbine applications firing natural gas – assuming < 12% wet H2O; Firing Temperatures>1200°F (649°C), we offer the following emission guarantees in HHV over turndown – without augmenting air:

| Non-Power Augmentation* | Power Augmentation** | |

| lb/MMBtu (mg/MJ) | lb/MMBtu (mg/MJ) | |

| NOx | 0.08 (34) | 0.08 (34) |

| CO | 0.04 (17) | 0.06 (26) |

| VOC | 0.004 (2) | 0.006 (3 kg/GJ) |

| PM-10 (front and back half) | 0.01 (4) | 0.02 (9) |

* > 11.5% wet O2 and Burner Inlet TEG Temperature > 850°F (454°C)

** > 10.5% wet O2 and Burner Inlet TEG Temperature > 750°F (399°C)

Features & Benefits

- Low CO and VOC Emissions

Up to 80% lower than recirculation type burners – including over turndown. - Low Pressure Drop

Maintained through our patented design with mixing vortices. - Reliable Light-off

High Energy Spark Ignition (HESI) for consistent performance in low oxygen and high water vapor environments. - No augmenting air required

With TEG oxygen greater than 10.5% and water vapor as high as 20%. - Investment Cast stabilizers

Stainless steel stabilizers allow for long life and consistent performance. - Vortex shedding analysis

Performed on each burner to ensure long life and trouble free operation. - Patented design

Provides increased mixing that optimizes the existing oxygen in the turbine exhaust. - Short Flame Lengths

Reduced downstream duct distance and improved temperature distribution from the burner.

adVantage® Technical Bulletin

Publication Number 404004-03