Product: SCR Reheating

Forney provides multiple options to ensure SCR efficiency at lower inlet operating temperatures. Our in-duct, external duct and perimeter fired burners provide unique solutions for this harsh environment.

Check out our article in Power Magazine covering this unique application.

Power plants must meet both stringent NOx reduction regulation and their customers’ needs of varying electricity demands by reducing their boiler’s steam production. Reducing boiler load causes lower flue gas temperatures reducing the operating abilities of NOx control equipment such as selective catalytic reduction (SCR) reactors. Forney Corporation utilized its vast combustion experience to develop a line of SCR reheaters to supplement flue gas temperatures. When firing conditions dictate the need for this additional heat, Forney’s

SCR reheaters pump heat into the flue gas stream, thereby maintaining a flue gas temperature that ensures maximum SCR efficiency. Forney can design a system for any configuration using one of three solutions, sure to satisfy your installation requirements.

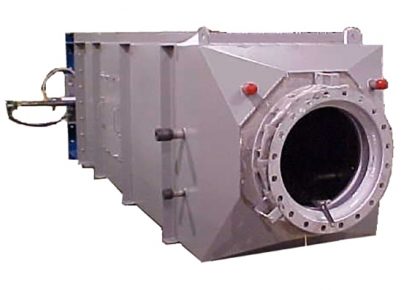

Forney was the first to introduce an external firing solution. This remedy is ideal for high ash environments because it eliminates the problems of slagging, ash build-up, and burner fouling by designing the combustion equipment to operate outside the boiler flue gas duct. Also, the external burners do not increase system pressure drop, making them ideal for retrofit applications.

When boiler arrangement or customer preference does not permit an external SCR reheater system, particularly in low dust flue gas streams, Forney’s reliable duct burner provides a compact in-duct burner system for flue gas temperature control. The duct burner solution minimizes heat input requirements and ongoing operating costs by providing reliable and even heat distribution for effective SCR operation.

Forney’s Perimeter-firing system combines the benefits of both in-duct and external duct firing solutions. Strategically mounted directly on the flue gas duct work, perimeter burners inject a high velocity, high temperature stream directly into the flue gas creating excellent heat distribution to the SCR, in either low or high dust applications.

| External | Induct | Perimeter | |

| Type | Grid Style or Register Style Burner | Grid Style Burner | High Velocity Burner |

| Applications: | High or low dust environments Space limited (register style) | Low dust environments Augment air system |

High or low dust environments Short mixing length |

| Fuel Consumption: | Natural Gas 17scfm per MMBtu (1.64 Nm3/min per MW) |

Natural Gas 17scfm per MMBtu (1.64 Nm3/min per MW) |

Natural Gas 17scfm per MMBtu (1.64 Nm3/min per MW) |

| Air: | 850 scfm per MMBtu (82.2 Nm3/min per MW) |

850 scfm per MMBtu (82.2 Nm3/min per MW) |

670 scfm per MMBtu (64.7 Nm3/min per MW) |

| Location: | Modular Installation | Installed in flue gas duct | Installed directly onto flue gas duct. |

- Customized Solution – offering external, in-duct, or perimeter fired SCR reheater systems. Our engineers will custom design and integrate the system appropriate for your plant.

- Reduced installation and capital expenditure cost – Compared to installing an economizer bypass system, a flue gas reheat system can save expense on installation and the loss of efficiency experienced with an economizer bypass system.

- CFD Modeling – Forney engineering can perform CFD modeling of heat distribution to assure efficient SCR operation.

- Experience – Forney technologies are proven in SCR and other firing applications around the world.

- Service – Forney service engineers provide start-up expertise and periodic maintenance capabilities to ensure your equipment operates reliably.

SCR Reheating Technical Bulletin

Publication Number 404002-13

SCR BROCHURE

Publication Number 404002-15