Product: PAF-II Low NOx burner

Proven Performance. Stable Operation.

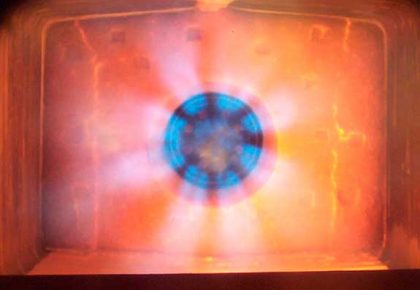

With its unique air mixing technique, the Forney PAF-II Low NOx Burner reduces NOx formation in a simple yet effective manner. The PAF-II Low NOx burner produces low NOx emissions through the dynamic interaction of the flame, combustion air and furnace combustion products. The foundation of the PAF-II design is the injection of a high velocity air stream around an inner core of low velocity air that both stages the air but also recirculates the products of combustion back into the flame which reduces the flame temperature.

The PAF-II burner does not contain many of the stationary or movable parts that complicate the operation and increases maintenance of other low NOx burners, such as spinner vanes, diffusers, swirlers, dampers or venturies.

Generally, a Forney low NOx burner package includes flame detectors, double block and vent assemblies, fuel trains, and a burner management system. Various control systems can be provided including single point positioning control and fully cross-limited control with oxygen compensation.

The PAF-II low-NOx burner is built by Forney Corporation. Forney has maintained its position as a leader in power plant and large industrial systems for more than 85 years by designing, manufacturing, installing and servicing the most innovative lines of combustion equipment.

Burner Components

Air Frame and Sleeve Damper

The PAF-II air frame design is based on the same design as Forney’s very successful Parallel Air Flow (PAF) design. The windbox air is directed through the burner in a parallel and non-spinning manner. This feature enhances the low NOx capabilities of the burner by carefully controlling the mixture of fuel and air for optimum NOx reduction. Each burner is supplies with a sleeve damper to shut off the air flow to out-of-service burners. The sleeve damper is pneumatically operated and is supported by sleeve bearings.

The Forney PAF-II Low NOx burner can retrofit to existing windboxes by providing a custom front plate designed to fit to the existing bolt pattern. In most cases, the original throat diameter does not need to be altered.

Gas Canes

Fuel gas is emitted to the burner through bevel tip gas canes in the low velocity air stream portion of the burner. Canes of this type have been proven by Forney on both new and retrofit low NOx applications. The tips are permanently positioned to direct the gas in the optimum direction for greatest stability and minimum NOx Formation.

Igniters

For your PAF-II burner, Forney provides our most reliable gas igniter, the MaxFire® with a HESI ignition source.

Flame Detectors

Forney’s complete line of Ultraviolet, Infrared or Dual Range flame detectors are available for both main flame and ignition flame detection.

Specifications

| Minimum | Maximum | |

| Capacity | 50 MBTU | 250 MBTU |

| Windbox / Furnance Differential | 4 in. WC | 8 in. WC |

| Throat Diameter | 22 in. | 54 in. |

| Windbox Depth | 24 in. | Unlimited |

| Burner Type (Canes) | 8 – 1.5″ | 12 – 2.0″ |

| Gas Pressure | 1 psi | 36 psi |

| Turndown | 1:1 | 5:1* |

| NOx Reduction | Up to 60% | Up to 60% |

| CO | <10 ppm | 150 ppm |

* Higher Turndown is available depending on site conditions.

Performance

Using the PAF-II Low NOx burner alone, Forney has proven NOx reductions of 40% on natural gas over legacy Forney burner designs. Further reductions in NOx of up to 80% can be achieved when other methods of control are employed, such as overfire air (OFA) and external flue gas recirculation (FGR).

The following table represents the NOx levels we would typically expect to achieve with the PAF-II Low NOx burner on three hypothetical boilers.

| Boiler | Fuel | Air Temp | NOx – lbs./MBTU* |

| A | Natural Gas | 100°F | 0.07 |

| B | Natural Gas | 540°F | 0.15 |

| C | Natural Gas | 640°F | 0.22 |

*Typical predicted emissions. Forney will be happy to provide NOx emissions predictions calculated specifically for your site upon request.

Reliable Operation

The parallel airflow design of the PAF-II Low NOx burner has its roots in the highly successful Forney PAF burner that is used for low excess air operation. All major burner components have previously been used in similar applications and have a long history of reliability and industry acceptance.

Flame Stability

The action of the high velocity air around the low velocity air provides a strong recirculation area in front of the burner which creates a stable flame front without the use of a diffuser or swirler. Turn down of 5:1 is common and can go lower in some cases.

Internal Flue Gas Recirculation

Furnace flue gas is recirculated back into the combustion zone through dynamic interaction of the high velocity and low velocity air streams. Flue gas recirculation into the combustion zone significantly reduces NOx formation by lowering the combustion flame temperature. This method of gas recirculation within the combustion flame envelope is very effective without incurring the major costs for fans, ducting, and controls that many other FGR systems require.

Simplified Maintenance

Forney burners use commonly available components, making them easy for the user to service.

PAF-II Low NOx Burner Spec Sheet

Forney Publication #404002-17