Product: Flexible Single Tube

This Class I igniter is located in a tilting tangentially fired boiler adjacent to the main fuel nozzle.

As an oil igniter, the unique rear atomizer results in a single tube extending to the one piece tip. This design eliminates the need for atomizer maintenance.

As a gas igniter, the gas is directed to the tip through the single flexible tube. Stabilization is maintained by a 7.5 inch swirler which creates a low pressure zone just down stream of the nozzle. Combustion air is provided from the windbox.

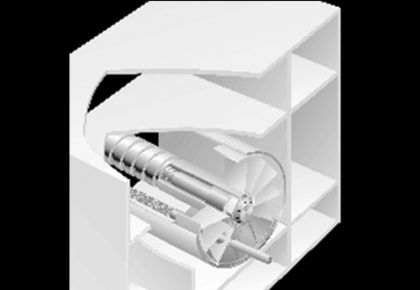

Forney’s Flexible Single Tube (FST) Igniter provides multi-fuel, stable and reliable ignition for tangential burners utilizing a flexible design for optimal ignition with tilting nozzles.

The Flexible Single Tube (FST) Igniter is a reliable source of ignition energy for use in a tilting tangential type boiler. It is a Class 1, continuous duty, igniter capable of burner ignition and low load support. It is easily installed in the auxiliary air nozzles between the main fuel elevations and is designed with flexible components to accommodate the tilting of the fuel nozzles. The FST Igniter is capable of burning liquid or gaseous fuels. With capacities up to 10% of boiler heat input, the FST improves boiler / turbine startup flexibility.

Each FST Igniter includes a flexible fuel gun, a flexible retractable High Energy Spark Igniter (HESI) and a flame detector with a flexible fiber optic assembly. The fuel gun has an air swirler at the furnace end which mixes the windbox air and fuel at the tip to create a stable flame. All major components are fixed to a burner front plate that is designed to match the existing bolt pattern at the burner front. All components are designed to freely tilt with the fuel nozzle through a ±30° angle. Flame detection is accomplished by the use of either an ultraviolet or infrared detector, depending on the fuel fired.

Optional equipment includes gun retraction, quick disconnect fuel and atomizing air couplings, as well as an electrical junction box.

Specifications

| Fuel: | No. 2 Oil or Natural Gas |

| BTU Rating: | Oil: 10 – 37 MBTU/hr Gas: 10 – 20 MBTU/hr |

| Fuel Pressure: | Oil: 60 – 125 psig Gas: 12 – 25 psig |

| Cooling/Combustion Air: | Flow: 40 SCFM Pressure: 6 WC |

| Guide Tube OD: | 2.38” |

| Mount Tube OD: | 2.88” |

| Length: | As Required, up to 8.5’ |

| Atomizing Pressure: | 20 psig (Differential over oil pressure) |

| Material of Construction: | Guide Tube and Mount Tube, Carbon Steel; Guide Tube Tip and Pilot Area, 304 SST |

| Retract Cylinder Air Pressure: (HESI/oil gun) |

60 to 100 psig |

HESI Specifications

| Input Voltage: | 120 to 240 VAC, 50/60 Hz |

| Input Power: | 120 VAC @ 1.5 A (2-A fuse); 240 VAC @ 0.75A (1-A fuse) |

| Output Voltage: | 2000 VDC |

| Output Energy: | 12 joules per spark |

| Spark Rate: | 3 per second (approximately) |

| Duty Cycle: | 50% at temp 0°F to 135°F (-18°C to 57°C) Ambient |

- Class 1 Igniter

Capacities up to 37 MBTU/hr which will support ignition under all credible burner light-off or operating conditions. - One Fst Igniter supports twO Fuel Nozzles

This arrangement results in half the number of igniters normally required. - Flame stability

The stainless steel 7 1/2” air swirler creates a low pressure zone at the tip for stable flame operation. - Low Opacity

The turbulent mixing of the fuel and combustion air caused by the swirler ensures low opacity during cold light-off. - easy retroFit

Can be installed between most fuel elevations with minimal or no burner

modification. - Reliable Ignition

Can be installed between most fuel elevations with minimal or no burner

modification.

FST Igniter Technical Bulletin

Publication Number 404006-05